Minuman cair profesional mengisi dan mengemas produsen mesin

| Place of Origin: | China,Jiangsu |

| Nama merek: | Jia Yuan |

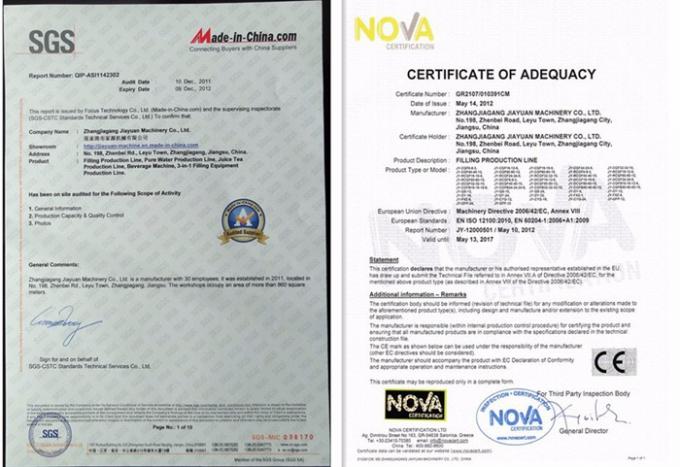

| Sertifikasi: | CE,SGS |

| Model Number: | CGF |

| Minimum Order Quantity: | 1 set |

|---|---|

| Harga: | USD 25000 per set |

| Packaging Details: | Export Wooden Case |

| Delivery Time: | 30 working days |

| Keywords: | drink water bottling machine | Production capacity: | 2000~40000BPH |

|---|---|---|---|

| Processing Types: | Washing Filling Capping | Function: | Bottle Washing Filling Capping |

| Filling precision: | less than 5 mm | suitable cap: | plastic screw cap |

| Cahaya Tinggi: | Botol Liquid Filling Machine,peralatan pembotolan air |

||

3 - in - 1 low noise water bottle filling machine pure water production line 500ml

Description:

How drink water bottling machine works

The plastic bottles are fed into the rotary rinser,filler capper by means of an input feed conveyor.A star wheel then transfers the bottle to neck holding gripper of the rinsing station.The rinsing robot indexes the bottle 180°and activates the rinsing value.Bottles after being rinsed are automatically transferred by a star wheel to the filling station.In the filling station the bottles are picked up by the neck and are allocated individual filling values.The state-of-art filling valve is so precise and accurate it gives even filling in all bottles.The filled bottles are then transferred to the capping station via a star wheel.The bottles automatically move for the capping stage where the caps release from the sorter on to the bottles.The caps are sealed automatically using special capping hands. The entire system is enclosed in a stainless steel/glass outer casing.After the capping stage the bottle are automatically ejected out to the out feed conveyor. The whole equipment is sleek and is capable of bottling various sizes of PET bottles ranging from 250 ml to 2 ltrs.

Filling sealing machine Features

1.Integrate Bottling Rinsing, Filling and Capping into one.

2.Including bottle infeed air conveyor,tri-bloc Rinser-Filler-Capper and outfeed conveyor and cap elevator.

3.All parts that contact the bottle and liquid are made of stainless steel or food grade plastic material

4.Infeed timing screw, indexing star wheel and guider are made from noise-reducing and low-wear plastic.

5.The sturdy base is supported by four feet and is made with stainless steel sheathing secured to the tubular frame.

6.All drive train components located inside machine base to be protected from aggressive environment, extended life, clean and unobstructed cabinet surface.

7.Bottles are rinsed internally and externally, No bottle, No Rinsing.

8.Precise and Accurate GRAVITY filling valves give even filling in all bottles at the same level, No bottle, No filling.

9.Magnetic capping head eliminates over-tightening of caps, No bottle, No capping.

10.PLC control and friendly touch screen HMI interface.

11.Adjustable speed by inverter.

12.Fast and easy changeover to various bottle sizes.

13.Unique design bottle neck suspend system makes bottle move smoothly.

14.Easy to operate,clean and maintain.

Parameter:

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 |

| Production capacity(500ml)(b/h) | 2000-4000 | 4000-6000 | 8000-10000 | 12000-15000(0.5L) |

| Filling precision | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) | ≤±5MMLiquid Level | ≤±5MM(Liquid Level) |

| Polyester bottle standard(mm) | Bottle diameter40-80; | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) |

| Height | Height:130-280 | (Height):150-320 | (Height):150-320 | (Height):150-320 |

| Suitable cap shape | Plastic Screw Cap | (Plastic Screw Cap) | Plastic Screw Cap) | (Plastic Screw Cap) |

| Water pressure of Washing bottle(MPa) | 0.18 | 0.18 | 0.18 | 0.18 |

| Water consumption for Water bottle (kg/h) | 800 | 1600 | 2500 | 3500 |

| Spraying position | 5 | 5 | 6 | 12 |

| Dripping bottle position | 3 | 3 | 3.5 | 7 |

| Gas source pressure(Mpa) | normal pressure | normal pressure | normal pressure | normal pressure |

| Gas consumption(m3/mm) | 0.3 | 0.3 | 0.4 | 0.5 |

| Total power | 4.23 | 5.03 | 6.57 | 8.63 |

| Total weight | 2000 | 3500 | 5500 | 8000 |

| Dimension(L*W*H) | 2100×1500×2200 | 2450×1800×2200 | 2750×2180×2200 | 3500×2200×2250 |

Machine in our factory:

Pls contact me and let's talk more details, thanks in advance!

Zhangjiagang Jiayuan Machinery Co., Ltd

Tel:+86-15962351473

wechat:15962351473

skype:Joyce1989280

whatsAPP:+8615962351473

Factory Add:

No.198,Zhenbei Road,Leyu Town, Zhangjiagnag City , JiangSu Province .PRC

POST CODE :215625

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Mesin Pengisi Botol Jus Untuk Botol HDPE, Mesin Pengisi Air

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Sepenuhnya otomatis jus mengisi mesin 4000BPH untuk bulat PET botol

Mesin Pengisi Botol Botol Plastik 6000BPH kaleng kaleng Hot Filling Machine

3 In 1 Juice Bottling Equipment Mesin Stainless Steel / Filling Capping

Mangga Juice Monoblock Mengisi Peralatan Untuk Botol PET 2000ml

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler